Product Description

Product Description:

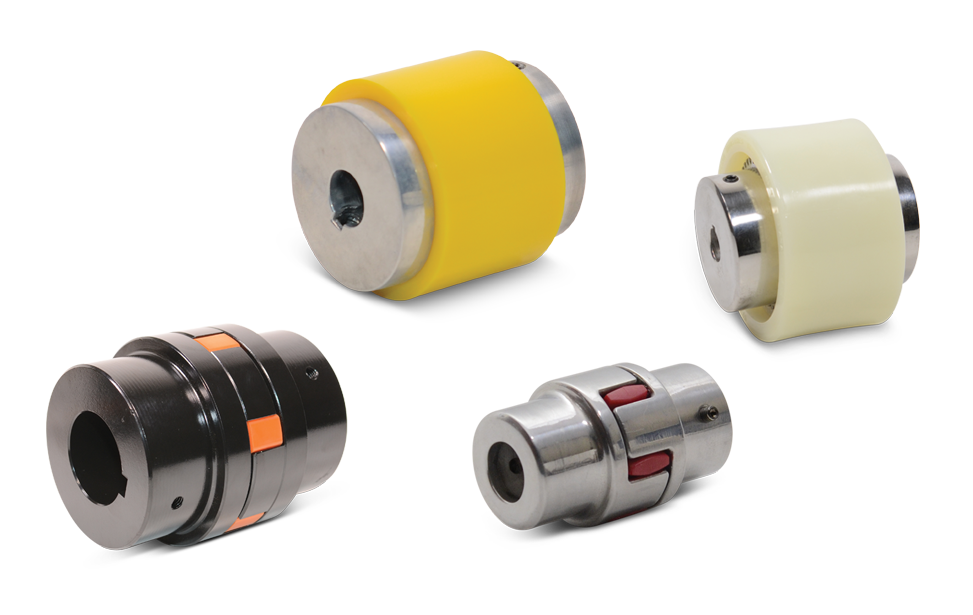

Coupling is used to link the 2 different organizations shaft (driving shaft and driven shaft) to rotate to common transmission torque of mechanical parts.The overloaded power transmission at high speed, some coupling and buffer, vibration and enhance the role of shaft system dynamic performance.Coupling consists of 2 parts, respectively, and the driving shaft and driven shaft connection.

| Brand | SHAC |

| Raw material | Aluminum |

| Inner Diameter | 4-60MM |

| Length | 25-140MM |

| Model number | JM1,JM2,JDM,JM-T,JH,TM1/TM2/TM3/TM4,JB,JG,JT |

| Packing | Plastic bag+inner box.According to customer’s request |

| Sample | Free sample and catalogue available |

| Certification | ISO 9001 , ISO 14001 , ISO 14000 |

| Application | CNC machines, medical and food machinery, fitness machinery, packaging machinery, printing machinery, and other machinery supporting equipment. |

Detailed Photos

Company Profile

Certifications

Our Advantages

Service:

1,Our Team:

We have experienced and qualified team of marketing and sales representatives to serve our valued customers with the finest products and unsurpassed service.And have professional engineers team to assessment and development the new precision products,and make the OEM customized more easily,experienced QC team to test the products quaity ensure the goods quality before delivery out.

2,Our products:

Quality is the life .We use only the best quality material to ensure the precision of our

Product.All products we sold out are strictly selected and tested by our QC department.

3,Payment:

We accept payment via TT (Bank transfer), L/C,Western Union.

4,Shipping method:

Including DHL, UPS, TNT, FEDEX,EMS, Airfreight and by Sea,as customer required.

To get sample or price list of linear gudies,ball screw, please contact us.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How to Select the Right Motor Coupling for Specific Torque and Speed Requirements?

Selecting the right motor coupling for specific torque and speed requirements is crucial to ensure optimal performance and reliability in a power transmission system. Here are the steps to guide you through the selection process:

1. Identify Torque and Speed Requirements:

Determine the torque and speed requirements of your application. Torque is the rotational force needed to perform the intended task, while speed refers to the rotational speed at which the coupling will operate.

2. Consider Operating Conditions:

Take into account the environmental conditions and operating parameters of your application. Factors such as temperature, humidity, and potential shock loads may influence the coupling’s performance.

3. Calculate Torque and Speed Ratios:

Calculate the torque and speed ratios between the motor and driven equipment. This will help you understand the required torque capacity and misalignment capabilities of the coupling.

4. Choose the Coupling Type:

Select a coupling type that aligns with your torque and speed requirements. For higher torque applications, consider gear couplings, while elastomeric couplings are suitable for lower torque applications with misalignment needs.

5. Check Torque and Speed Ratings:

Consult the manufacturer’s specifications to ensure the selected coupling can handle the calculated torque and speed requirements. Pay attention to both the continuous and peak torque ratings.

6. Misalignment Compensation:

If your application requires misalignment compensation, opt for flexible couplings that can accommodate angular and/or parallel misalignment.

7. Consider Critical Speed:

For high-speed applications, check the coupling’s critical speed rating. Operating near or beyond the critical speed can lead to resonance and coupling failure.

8. Verify Service Life:

Check the expected service life of the coupling under your application’s conditions. A coupling with a longer service life can reduce maintenance needs and downtime.

9. Budget and Cost:

Consider the budget and overall cost of the coupling, including installation and maintenance expenses. Balance the initial cost with the coupling’s expected performance and durability.

10. Seek Expert Advice:

If you are unsure about the best coupling choice for your specific requirements, consult with coupling manufacturers or industry experts who can provide valuable insights and recommendations.

By following these steps and conducting thorough research, you can confidently select the right motor coupling that matches your torque and speed requirements, ensuring efficient power transmission and prolonged equipment lifespan.

“`

Real-World Examples of Motor Coupling Applications in Various Industrial Setups

Motor couplings are versatile components used in numerous industrial applications to connect motors to driven equipment. Here are some real-world examples of motor coupling applications in various industrial setups:

1. Conveyor Systems:

In material handling industries, motor couplings are commonly used in conveyor systems to transmit power from motors to conveyor belts. The couplings provide flexibility to accommodate misalignments and shock loads, ensuring smooth and efficient material transportation.

2. Pumping Stations:

Motor couplings play a crucial role in pumping stations, connecting motors to pumps used for water supply, wastewater management, and various fluid transfer applications. The couplings help maintain precise alignment between the motor and pump shafts, ensuring efficient pump operation.

3. Machine Tools:

In machining and manufacturing processes, motor couplings are used in machine tools such as lathes, mills, and CNC machines. The couplings enable accurate transmission of torque, allowing for precise movements and cuts in metalworking operations.

4. HVAC Systems:

In heating, ventilation, and air conditioning (HVAC) systems, motor couplings connect motors to fans and blowers. The couplings help absorb vibrations and shock loads, improving the overall efficiency and lifespan of the HVAC equipment.

5. Packaging Machinery:

In the packaging industry, motor couplings are used in various packaging machinery such as filling machines, labeling machines, and cartoners. The couplings provide reliable torque transmission and help ensure precise positioning of packaging components.

6. Printing Presses:

In the printing industry, motor couplings are utilized in printing presses to connect the motor to the plate cylinders and impression cylinders. The couplings enable smooth and accurate printing operations, minimizing image misalignment and ensuring consistent print quality.

7. Mining Equipment:

In the mining industry, motor couplings are employed in heavy-duty equipment such as crushers, conveyors, and draglines. The couplings handle high torque and shock loads, allowing for efficient material handling and extraction.

8. Marine Propulsion Systems:

In marine applications, motor couplings connect engines to propellers or thrusters. The couplings accommodate the movement of the ship’s hull and ensure reliable power transmission for propulsion.

9. Food Processing Equipment:

In the food processing industry, motor couplings are used in mixers, grinders, and extruders. The couplings provide smooth and sanitary power transmission, meeting strict hygiene standards.

10. Renewable Energy Systems:

In renewable energy applications such as wind turbines and solar trackers, motor couplings connect motors to the mechanical components responsible for adjusting the turbine or solar panel orientation, optimizing energy capture.

Motor couplings are fundamental components in these and many other industrial setups, contributing to the efficiency, reliability, and performance of diverse applications across various sectors.

“`

Can a Damaged Motor Coupling Lead to Motor or Equipment Failure?

Yes, a damaged motor coupling can lead to motor or equipment failure if not addressed promptly. Motor couplings play a critical role in connecting the motor to the driven equipment and transmitting torque between them. When a coupling is damaged, several potential issues can arise:

- Reduced Torque Transmission: Cracks, wear, or deformation in the coupling can result in reduced torque transmission from the motor to the driven equipment. This may lead to inefficient operation and underperformance of the machinery.

- Mechanical Vibrations: Damaged couplings can introduce vibrations into the system, leading to increased wear and fatigue on connected components, such as bearings and shafts. Excessive vibrations can cause premature failure of these parts.

- Misalignment and Stress: If the coupling loses its ability to compensate for misalignment, it can subject the motor and driven equipment to increased stress and loading. This can result in premature wear and failure of bearings, shafts, and other components.

- Overload on the Motor: In certain coupling designs, damage may result in a loss of overload protection. Without the safety mechanism, the motor may experience excessive loads, leading to overheating and possible motor failure.

- Increased Downtime: A damaged coupling can cause unexpected breakdowns and unplanned downtime for repairs, affecting productivity and overall operational efficiency.

- Safety Risks: In extreme cases, a severely damaged coupling may disintegrate during operation, posing safety risks to personnel and surrounding equipment.

To avoid motor or equipment failure due to a damaged coupling, regular maintenance and inspection are crucial. Visual inspections, vibration analysis, and monitoring of coupling performance can help identify signs of damage early on. If any issues are detected, it is essential to replace or repair the damaged coupling promptly to prevent further damage and ensure the reliable operation of the machinery.

Proper selection of high-quality couplings, appropriate for the specific application and operating conditions, can also reduce the likelihood of coupling failure and its potential impact on the motor and equipment.

“`

editor by CX 2024-04-04

by

Tags:

Leave a Reply