Product Description

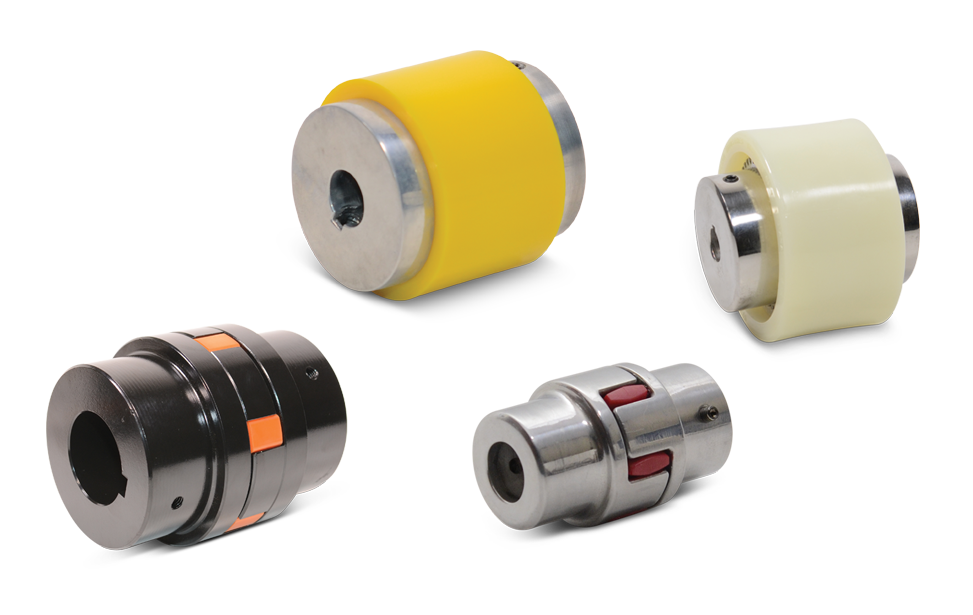

Densen Customized CNC Motor Jaw Shaft Coupling, Industrial Equipment Flexible Coupling Wholesale

| Product Name | CHINAMFG customized CNC motor jaw shaft coupling, industrial equipment flexible coupling wholesale |

| DN mm | 12~160mm |

| Rated Torque | 25~25000 N·m |

| Allowable speed | 15300~1500 N·m |

| Material | 35CrMo/ZG270/45# steel/Aluminum alloy |

| Application | Widely used in metallurgy, mining, engineering and other fields. |

Product show

Company Information

HangZhou New CHINAMFG Casting and Forging Company is the sales company of HangZhou CHINAMFG Group of Companies. Features of New CHINAMFG simply summarized as below:

1. Trusted supplier of steel, iron & non-ferrous components;

2. Extensive documented quality program in place.

3. Castings, forgings, stampings, machining, welding & fabrication services.

4. 9 related factories, over 50 joint-venture sub-contractors.

5. 25+ years of manufacturing experiences, 10+ years of exporting experience

6. 100% of products sold to overseas customers.

7. 50% of customer base is forturne 500 companies.

Processing support

Casting Service:

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify.

New Densen offers multiple investment casting, sand casting, permanent casting, die casting, low pressure casting, ESR casting, lost foam casting, etc. Material can be handled include steel, iron, non-ferrous. Single component weight range is from 0.01Kg to 150 tons separately.

Forging Service:

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. New CHINAMFG offers open die forging, closed die forging and ring forging services. Material can be steel, iron and non-ferrous. Material can be handled include steel, iron, non-ferrous. Single component weight range is from 0.1Kg to 50,000Kgs.

Stamping Service:

Stamping (also known as punching) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape.

New Densen-XBL has more than 60 sets stamping equipments, is the designed supplier for several famous bands automotive companies, has the full ability to offer whole processes from blanking, stamping, welding, to electrostatic spraying for CHINAMFG customers.

Welding & Fabrication Service:

Welding Frabrication is the fabrication process of metal structures by cutting, bending, then assembling the components together through welding

New CHINAMFG offers manual arc welding ,laser welding and robot welding etc. UT, MPT,RT,PT all are available used for inspection, WPS &PQR (Welding Process Specification& Procedure Qualification Records) before production is available under clients’ requirement.

Machining Service:

Machining is any of various processes in which a piece of raw material is cut into a desired final shape and size by a controlled material-removal process.

New Densen-XBL has more than 60 sets precision machines incl. CNC center, boring, milling, lathing, etc., and more than 300 inspection instruments incl. 3 sets CMM with grade μm. Repeated tolerance can be maintained as 0.02mm. Meanwhile awarded by certificates ISO9001-2008; ISO/TS16949. New Densen-XBL specialized in high precise machining for small-middle-big metal components.

3rd Party Inspection:

New Densen worked as 3rd party inspection center besides its sister factories or sub-contractors’ self inspection, Offers process inspection, random inspection and before delivedry inspection services for material, mechanical, inside defects, dimentional, pressure, load, balance, surface treatment, visual inspection and test. Weekly project follow-up report together with pictures and videos, full quality inspection documentation available.

New CHINAMFG also designed as 3rd party inspection representative for several customers when their products made by other suppliers.

Application:

FAQQ1. Are you a manufacturer or a trader?

Manufacture, we have 5 own foundries, 4 in ZheJiang Province, 1 in ZHangZhoug Province

Q2. Do you have MOQ request?

1 pcs per order is ok with us , unless material is seldom used.

Q3. If I only have a sample,without drawings, can you quote then manufacture for me?

Just send us the sample, we would have the sample simulated and measured by professional equipment then issue formal drawings for

you , at the same time, we could help you optimize the design according to your demand and related processes’ feasibility.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Understanding the Torque and Misalignment Capabilities of Motor Couplings

Motor couplings play a crucial role in transmitting torque from the motor to the driven equipment while accommodating certain degrees of misalignment between the shafts. Here’s a detailed explanation of their torque and misalignment capabilities:

Torque Transmission:

Torque transmission is one of the primary functions of a motor coupling. It refers to the ability of the coupling to transfer rotational force (torque) from the motor shaft to the driven equipment shaft. The torque capacity of a coupling depends on various factors, including:

- Coupling Type: Different coupling types have varying torque capacities. For instance, gear couplings have high torque capacity, making them suitable for heavy-duty applications.

- Material and Design: The material and design of the coupling elements play a role in determining its torque capacity. Couplings made from high-strength materials can handle higher torque loads.

- Size: The size of the coupling affects its torque capacity. Larger couplings generally have higher torque ratings.

- Operating Conditions: Environmental factors, temperature, and speed also influence the torque capacity of the coupling.

Misalignment Compensation:

Motor couplings are designed to accommodate a certain degree of misalignment between the motor and driven equipment shafts. Misalignment can occur due to factors such as manufacturing tolerances, thermal expansion, and operational conditions. The misalignment capability of a coupling depends on its type and design:

- Flexible Couplings: Flexible couplings, such as jaw couplings or elastomeric couplings, can handle both angular and parallel misalignment. They provide some flexibility to dampen vibrations and compensate for minor misalignment.

- Universal Joints: Universal joints can handle angular misalignment and are commonly used in applications requiring a high range of motion, such as vehicle drivelines.

- Disc Couplings: Disc couplings can handle angular misalignment and provide high torsional stiffness for precision applications.

- Bellows Couplings: Bellows couplings are suitable for applications requiring high levels of parallel misalignment compensation, such as in optical equipment.

It is essential to consider the torque and misalignment requirements of the specific application when selecting a motor coupling. Properly matching the coupling’s capabilities to the system’s needs ensures efficient torque transmission and helps prevent premature wear or failure due to misalignment issues.

“`

How to Identify Signs of Wear or Failure in a Motor Coupling?

Regular inspection of motor couplings is essential to detect signs of wear or potential failure. Identifying these signs early can prevent unexpected breakdowns and ensure the safety and efficiency of the power transmission system. Here are some indicators to look for:

1. Visible Damage:

Check for any visible damage to the coupling components, such as cracks, chips, or deformations. These may indicate stress or excessive wear.

2. Abnormal Noise:

Listen for any unusual noises during operation, such as rattling, clicking, or grinding sounds, which could suggest misalignment or component damage.

3. Vibration:

Excessive vibration during operation may indicate coupling misalignment or component wear.

4. Temperature Changes:

Notice any significant increases in the temperature of the coupling during operation, as it may suggest excessive friction or improper lubrication.

5. Misalignment:

Check for any misalignment between the motor and driven equipment shafts, as misalignment can lead to accelerated coupling wear.

6. Excessive Backlash:

If you observe excessive play or free movement in the coupling when changing rotational direction, it may indicate increased backlash and potential coupling wear.

7. Lubrication Issues:

Inspect the coupling for signs of insufficient or contaminated lubrication, as improper lubrication can lead to increased friction and wear.

8. Increased Downtime:

If you notice more frequent maintenance or unplanned downtime, it may be a sign of coupling wear or potential failure.

9. Shaft Movement:

Observe any axial or radial movement in the motor or driven equipment shafts, which could indicate coupling wear or misalignment.

10. Age and Usage:

Consider the age of the coupling and the total operating hours. Older couplings or those subjected to heavy usage may be more susceptible to wear and require closer inspection.

If you identify any of these signs, it’s essential to address the issue promptly. Depending on the severity of the wear or failure, the appropriate action may involve adjusting the alignment, replacing worn components, or replacing the entire coupling. Regular maintenance and inspection schedules can help catch potential problems early and extend the life of the motor coupling, contributing to a more reliable and efficient power transmission system.

“`

Can a Damaged Motor Coupling Lead to Motor or Equipment Failure?

Yes, a damaged motor coupling can lead to motor or equipment failure if not addressed promptly. Motor couplings play a critical role in connecting the motor to the driven equipment and transmitting torque between them. When a coupling is damaged, several potential issues can arise:

- Reduced Torque Transmission: Cracks, wear, or deformation in the coupling can result in reduced torque transmission from the motor to the driven equipment. This may lead to inefficient operation and underperformance of the machinery.

- Mechanical Vibrations: Damaged couplings can introduce vibrations into the system, leading to increased wear and fatigue on connected components, such as bearings and shafts. Excessive vibrations can cause premature failure of these parts.

- Misalignment and Stress: If the coupling loses its ability to compensate for misalignment, it can subject the motor and driven equipment to increased stress and loading. This can result in premature wear and failure of bearings, shafts, and other components.

- Overload on the Motor: In certain coupling designs, damage may result in a loss of overload protection. Without the safety mechanism, the motor may experience excessive loads, leading to overheating and possible motor failure.

- Increased Downtime: A damaged coupling can cause unexpected breakdowns and unplanned downtime for repairs, affecting productivity and overall operational efficiency.

- Safety Risks: In extreme cases, a severely damaged coupling may disintegrate during operation, posing safety risks to personnel and surrounding equipment.

To avoid motor or equipment failure due to a damaged coupling, regular maintenance and inspection are crucial. Visual inspections, vibration analysis, and monitoring of coupling performance can help identify signs of damage early on. If any issues are detected, it is essential to replace or repair the damaged coupling promptly to prevent further damage and ensure the reliable operation of the machinery.

Proper selection of high-quality couplings, appropriate for the specific application and operating conditions, can also reduce the likelihood of coupling failure and its potential impact on the motor and equipment.

“`

editor by CX 2024-04-29

by

Tags:

Leave a Reply